Our state-of-the-art profile rolling mill for heavy sheet piles and special profiles was planned, constructed, and commissioned in 2018 after the KOHE Group completed a process layout for sheet pile production with widths of 400-900 mm in U- and Z-form. Production started in the first quarter of 2019.

Hebei Jinxi Sheet Pile & Section Technology Co., Ltd. — Our Rolling Mill for Sheet Piles, Special Profiles and Heavy Beams

The standard production lengths for sheet piles in the factory are 6 to 32 meters, the maximum productionable length is 36 meters. The production capacity for steel sheet piles and beams is 1 million tons per year.

All well-known international standard steel grades can be produced at the Hebei Jinxi Iron and Steel Group steel mill. The production, tolerances, and composition of the steel grades are carried out according to international standards such as DIN EN 10248, ASTM, or JSSC.

Production according to German Requirements

The sheet piles are manufactured based on German engineering. The sheet piles, up to 36 meters long, are manufactured on the production line and, if necessary, compressed and pressed into double planks. The material is provided according to the requirements of the products to be manufactured.

In addition to the sheet pile, special products such as large H-beams with an extra-middle bridge and oversized U-profiles for the construction of particularly large harbor walls leave the production line.

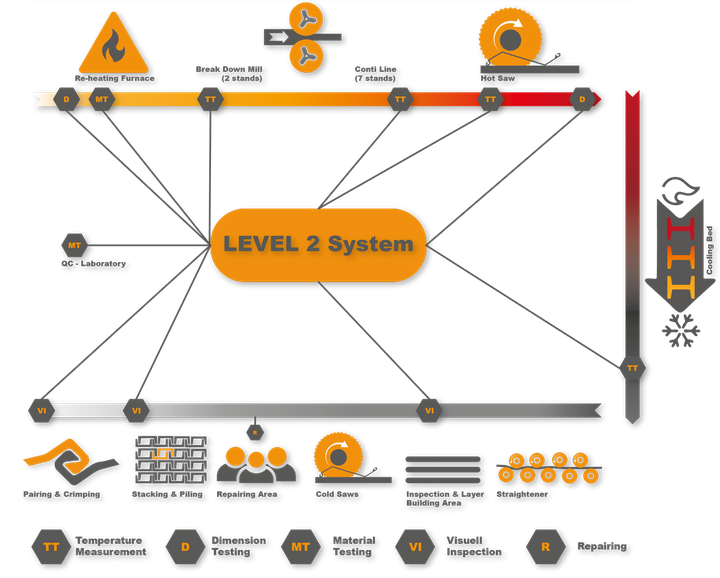

Production & Quality System

Health and Safety

We, Hoesch Spundwand und Projekte GmbH, are committed to a high standard of maintaining the health and safety of our employees, customers, and contractors, as well as sustainable environmental protection. Our focus is on energy efficiency and environmental friendliness. Due to this, our factory has already installed high-performance filters that reduce emissions and minimize waste.

Safety Measures in our Rolling Mill

01

Regular Safety Committee

In order to examine and continuously ensure the safety, health, and cleanliness of our rolling mill, a safety committee meets regularly in our state-of-the-art facility.

02

Annual Inspection

In our annual safety inspection, all electrical equipment is subjected to an inspection by specialist personnel (analogous to BGV A3/DGUV V3).

03

Health and Safety Instructions

Our safety engineers and safety officers carry out all relevant health and safety instructions and measures for our employees on site.

International Warehouse Locations

Hoesch Spundwand und Projekte GmbH has large, central storage areas in Asia and Europe. We supply our customers in Europe from our central warehouse in Moerdijk, the Netherlands. This provides access to continuously more than 10.000 tons of sheet piles of different U- and Z-profiles, which are available as a starting quantity for large projects or as a project quantity even without large advances at a very short notice.

The Right Sheet Piles for you in Stock

With our standard profiles and lengths of up to 24 meters, most construction projects can be operated immediately. Our standard steel grade, S355GP, meets or exceeds the usual requirements of most construction sites and projects.

For the most part, individual processing is still carried out on site in our warehouse, so that the sheet piles are always exactly adapted to your project. Processes that we cannot carry out ourselves, such as the application of coating systems, the insertion of special seals, or the production of special construction planks, are taken over by our nearby partner companies.

Location & Connection to our European Warehouse

The warehouse in Moerdijk is centrally located in Europe on the south bank of the Dutch Deep. This geographical location creates a sustainable distribution center of sheet piles in Europe through short transport routes. The port of Moerdijk has a trimodal connection, so the sheet piles can be delivered directly to your construction site if required by ship, train, truck, or combined. Our logistics department always finds the fastest and best solution, even for your unloading on the construction site.

Warehouse Location in Asia

A second storage facility is located in Asia in the immediate vicinity of the rolling mill near the seaport of Tianjin, China. From this warehouse site, 3000 to 5 000 t of sheet piles of different profiles are continuously available, which shortens the delivery time, especially for international projects, and thus enables a quick project start.